flow rate calculator 3d printer

In the posts about E-step Setting we discussed on how to adjust the the length of filament that is pulled in by the extruderIt is one of the important settings for having a high quality 3D printing. Copy the serial by just selecting it in the window.

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

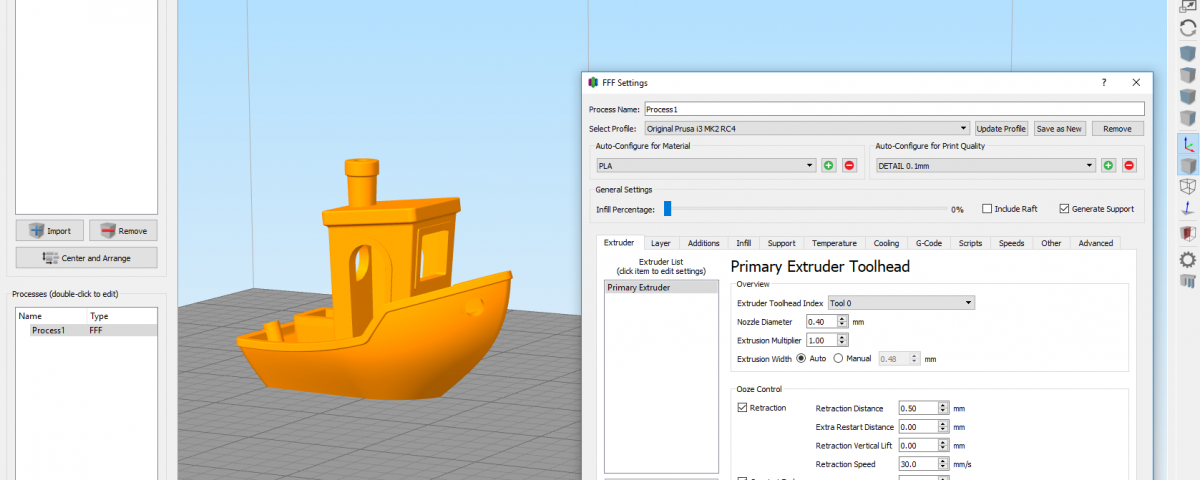

In IdeaMaker you need to edit the Flowrate under Primary Extruder - Filament Settings - Flowrate It is recommended to repeat step 2 and 3 to make sure the new flow rate value is correct and the measured wall size is close to the expected value.

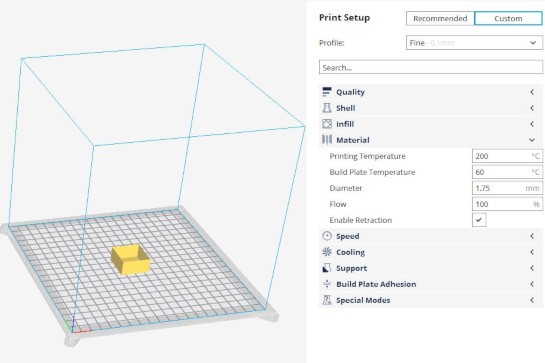

. The default value for the flow rate is usually 100. Now from within the 3D slicer set bottom layers to 1. This should be done on every new reel of filament.

Finally slice and export the cube to the SD card. Flow compensation is used to compensate for the expansion of the filament being pressed against the layer underneath. I use an ender 5 plus which hasnt got an entry point for e steps when stock meaning I.

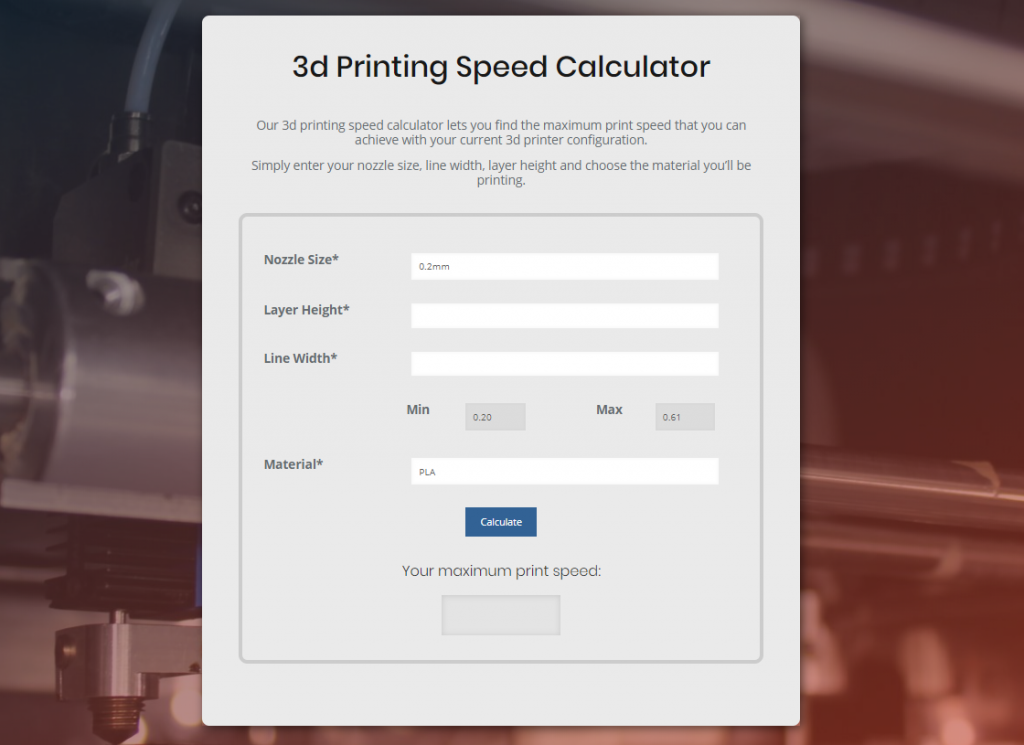

Using these settings the 3D printer figures out how fast to run the extruder motors to send enough filament for printing through the hotend. 3d Printing Speed Calculator Our 3d printing speed calculator lets you find the maximum print speed that you can achieve with your current 3d printer configuration. With 100 flow rate the cube is oversized.

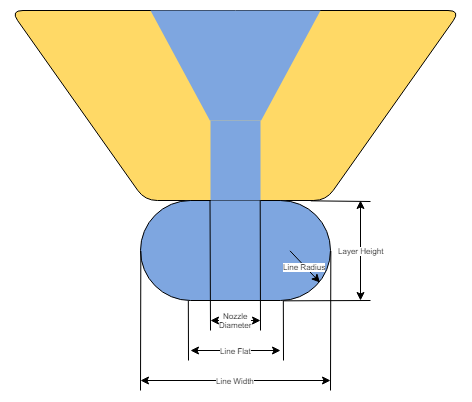

If You enjoyed this guide and You want to say Thank You please consider supporting me by sending a tip on thingiverse or my PayPal here. Use the custom start gcode feature to insert. A extrusion width identified in Step 52 b layer height2 c print speed.

In fact a high percentage of the 3D printing defects is related to. If you set the flow rate to 1 you will see a 1 meter drop in the flow rate. Nozzle of 040 mm width of layer 080 mm to create two outer layers and make the measurement more accurate and flow rate of 100.

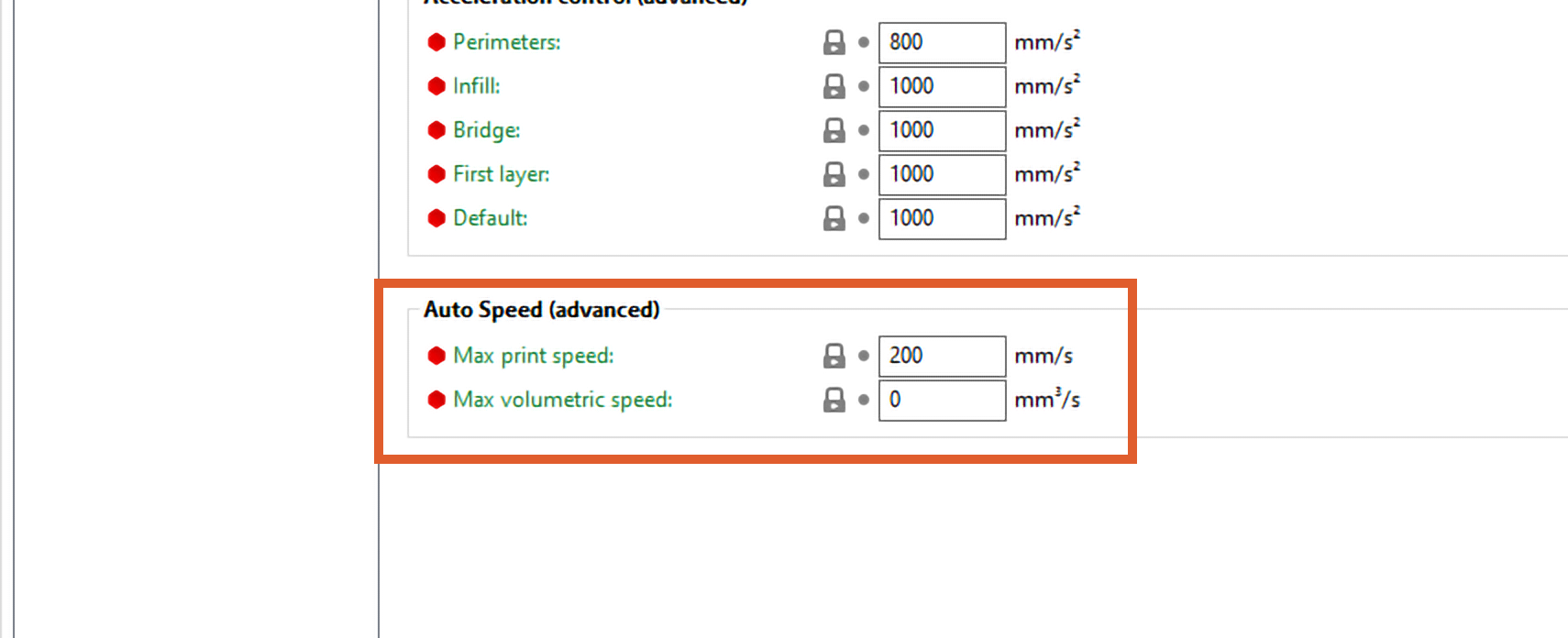

Printing a 06mm track from a 04mm nozzle. This is the method I have elaborated by merging a few other methods and. Recommended maximum speed maximum flow rate layer height extrusion width to calculate the maximum printing speed.

To correct this deviation we will. Use the calculator below to find out your safe maximum flow rate. This is typical for most printers as purchased.

For instance if your 3D printer is pushing 2 millimeters of filament per second when it actually should be pushing 25 millimeters instead you can use a flow rate compensation factor of 125 which will add an extra 05 millimeters of movement for each second of extrusion. I found a difference in dimensional accuracyprecision between flow rates 100 and 099. Lets assume that the max.

Calculate the maximum flow rate. How Do You Calculate 3d Printing Flow Rate. Input the average velocity of the flow.

This flow rate calculator uses flow velocity and cross-sectional flow area data to determine the volumetric flow rate of liquid. Default flow rate is set to 1 by default. It is necessary but not enough.

Select the shape of the cross-section of the channel. Now that you have a safe maximum flow rate calculated you can convert this. Measure the thickness of the printed wall to ensure extruder flow accuracy.

Print a 20mm cube in vase mode with a single base layer single wall only and no top layer. Filament Flow Rate Calculator. Flow Rate Calibration Guide 3DMaker Engineering Flow Rate Calibration Overview.

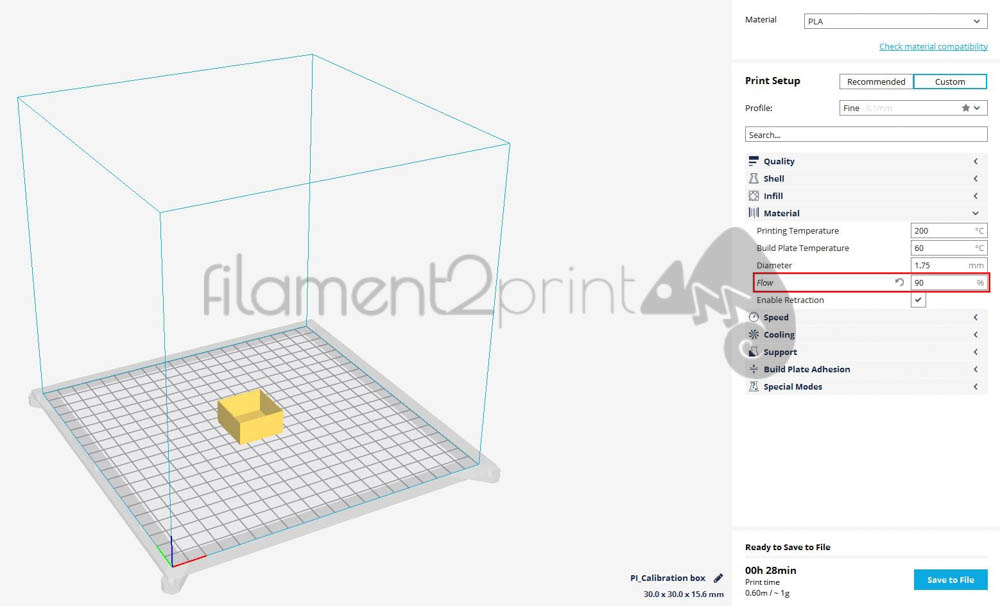

When using PLA with 100 flow rate recommended 90 we have obtained a measurement of 088 mm clearly oversized. Extrussions speed is F600 then divide the 600 by 60 to get the speed mm this would be 10 mm second here. If I have more time at some point it would be interesting to print a bunch of replicates and see how sensitive this stuff really is.

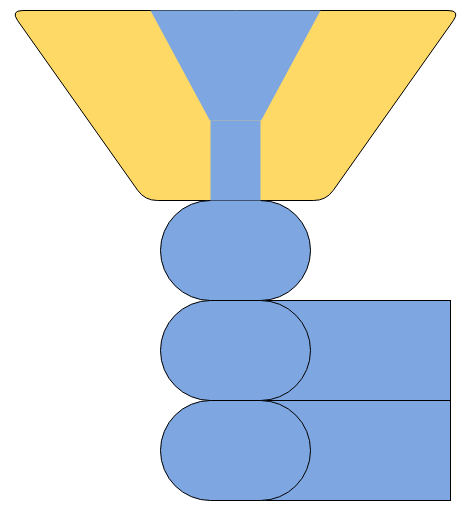

The flow rate also known as extrusion multiplier is a slicer setting that determines the amount of plastic a 3D printer will extrude. Max flow rate 10 pi 1715 2 2 10 314 175 2 175 2 2405 mm³ s Maximum flow rate calculator Printer settings for the extrusions multiplier. With a 04mm nozzle and a flow rate of 1 or 100 the thickness of a single wall should be 04mm.

Remember the width of the track is usually the same as the nozzle diameter although it is often better to print a wider track if you want improved mechanical performance eg. A 3D printers flow rate or extrusion multiplier is determined by the slicer setting that determines how much plastic is extruded. In Simplify 3D you need to edit the Extrusion Multiplier value.

Note their is a chance that flash may fail and usually this will place the board into a bootloader mode like original install does when you hit. A volcano-type is closer to 20-30mm 3 s whilst E3D claim 110mm 3 s for their super volcano. Calibrating your flow rate extrusion multiplier will ensure you are getting the optimal volumetric flow from your hot end.

Input all the measurements required to compute the cross-sectional area. Is this something for a specific slicer or is polymer volume flow and filament speed an output that needs to be used in an equation for flow rates. Set the wall count to 2.

Enter make flash FLASH_DEVICE and paste your serial after the. How To Calibrate 3D Printer Flow Rate. Set infill to 0.

Flow rate of 090. This will all you to produce dimensionally accurate prints. Set the top layers to 0.

Calibrating the flow rate will involve printing a test cube and measuring its walls to identify the actual flow rate compared to the flow rate value. Please see the note on the bottom of the flow tab for instructions on adapting this to your printer. If we know the maximum flow rate of the hot end we can use this formula.

Simply enter your nozzle size line width layer height and choose the material youll be printing. After this process mating parts should also fit together correctly. It depends on the slicer whether it is 0 or 100.

You can calculate the flow rate in five simple steps. In this post we will learn about calibration of material flow rate in the 3D printers. The printing parameters are.

Lets assume that we have a maximum flow rate of 1386 mm³ and we want to print with a layer height of 02 mm and a layer width of 048 mm. I have tested a lot of different flowrate calibration methods on the internet but methods I found were not accurate time-consuming or just were not working for me. Remember to reset the flow rate in the slicer to either 100 or 100 if the slicer uses a multiplier.

To use this calculator print a 20mm x 20mm x 20mm cube in vase mode and then measure the top 5 layers with your caliper. Use this calculator correct for the expansion of the filament by adjusting the flow rate. Measuring the calibration cube.

Nozzle priming has been turned off to avoid bed clips or problems with delta printers.

Prusa Knowledge Base Max Volumetric Speed

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

What Is The Flow Of 3d Printing And How To Adjust It

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

What Is The Flow Of 3d Printing And How To Adjust It

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

How To Calibrate Your Extruder E Steps Flow Rate Perfectly 3d Printerly

What Is The Flow Of 3d Printing And How To Adjust It

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calibration Of The Flow Rate Extrusion Multiplier Of Our 3d Printers Just One Important Step Youtube

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner